Generators are among the most used portable sources of power be it in the home, office, RV or work site. While small in size, generators produce enough power to injure and even kill an adult. This occurs when the proper precautions aren’t taken when using the generator.

Proper generator grounding is necessary to prevent risks such as electrocution which in most cases results from poor connections to appliances. Either of these causes can be prevented and reduced with proper wiring and grounding. You can ground in earth or the body of the generator can act as the ground.

This is a guide on why you need to ground a generator and how to do it properly. We also go into other precautionary measures you need to take care of to keep the generator and yourself safe when using it for power production. For most users, grounding a generator is easy given their use case scenarios.

Generator grounding requirements

According to OSHA (Occupational Safety and Health Administration), your portable or vehicle-mounted generator can either be grounded in the earth or the body of the generator used as the ground. You can only use the frame of the generator as a grounding base in the following cases:

- If the generator is only supplying power to appliances connected to the generator and plug-connected equipment with receptacles on the generator.

- If the metal noncurrent-carrying parts such as the tank, engine block and others are directly connected to the frame of the generator and the grounding conductor terminals are also bonded to the frame of the generator.

If these conditions are met, then you don’t need a grounding rode to ground the generator to the earth. If either one of them doesn’t hold, then you’ll need a grounding rode for the grounding. For example, if the generator will be supplying power to a given location through a transfer switch, you will simply need a grounding electrode.

Generator grounding rod and its role

A grounding rode is required when the above conditions are not being met. It’s used to provide grounding by driving it into the ground then connecting it to the generator with a solid copper wire (with only a single wire in the insulation). The rod should be made of a good electrical conductor such as copper and be at least 4 feet in length and about 3/8 inches in diameter. The whole rod is drove into the ground leaving a small part for connecting the grounding cable to.

The Grounding Process

For the grounding process, you’ll need the following items:

- Set of wire strippers: to connect the copper grounding rod to the generator, you’ll need to strip the ends of the copper wire connecting the two. With a set of wire strippers, you can easily do that. A sharp object such as a knife or pincer can also do the job if used correctly.

- Copper ground rod: the grounding rod is a necessity as shown in the conditions above. It’ll need to be at least 4 feet long and 3/8 inches thick. You should read the label to be sure of how long the rod needs to be driven into the ground to have the right amount of grounding.

- Pair of pliers: a pair of pliers is needed to properly wind the copper wire on the generator and around the grounding rod. The pair of pliers can also be used to cut and strip wires before using them.

- Water: if you’ll be dealing with hard ground, you can loosen up the soil with water before driving the rod into it.

- Shovel: if the ground is rocky and you can’t directly drive the rod into it, you can then opt to bury it into the ground with the help of the shovel.

- Solid copper grounding wire: the wire to be used to connect the grounding rod to the generator should be a solid one for the best grounding. It should be at least 25 feet in length but much less of it can be used.

- Hammer/sledge hammer/mallet: a good mallet, hammer or sledge hammer is needed to drive the rod into the ground. Be careful not to damage the rod when driving it down with the hammer.

- Wrench: the wrench is used to loosen the bolt on the generator and tighten it when one end of the grounding wire has been attached to it.

- Screwdriver: if the grounding bolt isn’t the type to be used with the wrench, a screwdriver can be used instead.

These items will make it easier and faster to ground your generator.

The procedure for grounding your generator with the grounding rod is as follows:

1. Install the copper grounding rod

You should use a hammer, sledge hammer or mallet to drive the copper ground rod into the ground for at least 8 feet below the surface. If the ground is too tough, you can soften it with water. If the ground is rocky in nature such that you can’t just drive the rod into it, you can bury the rod into the ground at an angle not more than 45 degrees.

2. Connect the coper wire to the copper rod

Strip one end of the solid copper wire then wind it tightly around the top part of the rod to make a secure and tight connection. This end of the wire should be followed by an insulated part all the way to the other end.

3. Ground the generator

Strip the other end of the copper wire then locate the grounding bolt on the side of your generator. Loosen the bolt then wind the wire on it before tightening the bolt again. Make sure the connection is secure and tight to provide a stable grounding connection.

Once the procedure above has been completed, you need a qualified electrician to test the whole connection with the right equipment. When testing, the ohmic resistance ought to measure almost zero and should be stable. If intermittent, it’ll be a sign of a loose connection which need fixing.

Why does a portable generator need to be grounded?

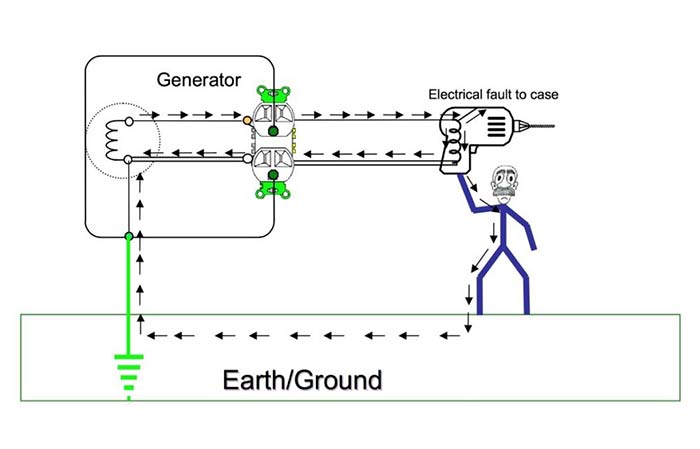

By definition, grounding is connecting an electrical circuit to a reference ground. The primary reason you need to ground your generator is to prevent electrocution and electric shock in general. Grounding also has the benefit of reducing the burning and melting effects of electricity on appliances. This often leads to damaged parts that require being replaced.

Grounding also prevents mechanical shock in circuits and components which are exposed to ground fault. This is different from electric melting and burning of appliances as it leads to the short-circuiting of the affected parts and appliances. Most importantly, grounding prevents damage and injury to any personnel who caused ground fault or are in close proximity to the electric circuit.

The other benefit of grounding is the reduction of the line voltage dip which occurs as one clears the ground fault. This way, the connected appliances won’t run the risk of damage. Lastly, grounding has the benefit of securing transient over-voltages in an effort to avoid facility shutdown.

You can check whether the generator needs to be grounded or not by checking its manual. If the manual isn’t clear or not available, you can look at its construction. If its transfer switch gives you the option to transfer current to a neutral ground conductor, the generator would have components that are from a separately derived system. Such a generator requires to be grounded independently with a grounding rod.

Safe work practices with generators and tools

Some of the safety measures to put into practice when using portable generators include the following:

- Always follow the manufacturer’s manual when using and maintaining a generator for safety purposes.

- Make sure to only plug electrical appliances directly into the generator with the cords supplied by the manufacturer and not others. If you use other cables, make sure they match the power rating of the ones from the manufacturer. Whatever cables you use need to be heavy-duty and have a 3-wire flexible cord and a 3-pronged cord connector with a grounding conductor.

- Use the provided (or bought) ground-fault circuit interrupters (GFCIs) as instructed by the manufacturer. This helps prevent current leaks and reduce the risk of electrocution as a result of that.

- Always inspect the generator and any other connected appliances before starting it up. If you find any risk of electric shock, do not use the generator. If there are parts to be fixed, fix them before use.

- Without a properly installed open-transition transfer switch, never attach a generator directly to an electrical system as you run the risk of damaging the appliances and even causing electric shock to the connected items.

- Always make sure the generator has the right bonding and grounding to prevent electrocution and shocks before use.

- Never use underrated cords with your generator and appliances. It is much better to use overrated ones than underrated ones.

- Use only double-insulated equipment and tools for safety purposes.